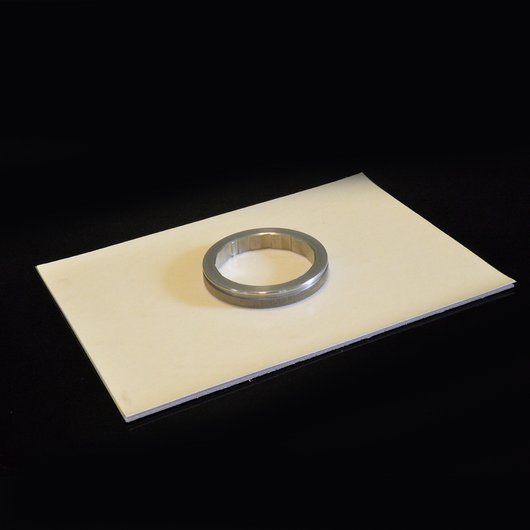

VCI skinboard ABRIGO

“Skinning” is a fixing process. Mostly smaller parts are distributed on a board blank with skinboard according to a certain pattern and then surrounded by a heated VCI film, which seals firmly with the skinboard into the gaps. The ABRIGO skinboard is coated with VCI to protect the bare metal parts against corrosion when in contact.

VCI skinboard can be made of corrugated or solid board. The VCI ski board can be processed to be between 100–1,600 mm width and 2,100 mm length.

Typical applications:

- Small to medium-sized parts (maximum height up to 12 cm, depending on machine and weight)

- Spare and individual parts

- If visibility is desired, also applicable for self-service distribution

- For pre-counted installation components