You can rely on our quality promise!

Consistently high quality of our products and services is our top priority. Our claim is to always offer you flawless and effective corrosion protection and to meet your requirements one hundred percent. We achieve this through our ISO 9001:2015 certified quality assurance system, which includes the following points:

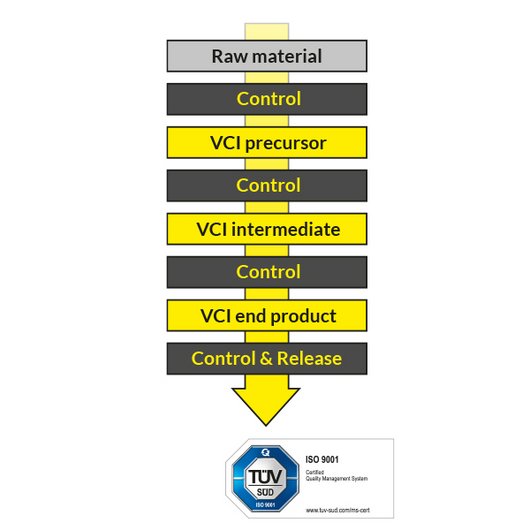

- Quality control

- from goods receipt: does the delivered raw material meet our specification?

- for preliminary, intermediate and final products: are all EXCOR and customer characteristics given? Specifications achieved?

- of all parameters defined between EXCOR and the customer, e.g. VCI concentration, corrosion protection effect, mechanical properties.

- Traceable and documented manufacturing process

- Exclusive use of suitable/defined input materials

- EXCOR products are only delivered to downstream processes or customers when all specified parameters have been checked and all requirements have been met

And this also speaks for EXCOR

- Our quality management system and laboratory methodology are TÜV-certified and regularly monitored.

- Our environmental management is certified according to ISO 14001:2015.

- EXCOR products are approved and successfully used by leading manufacturers in large-scale industry.

- At the request of our customers, we carry out climate simulation tests on complete packaging units. The load is adjusted to the type of transport, route and destination. After a few days, it is clear whether the goods, packaging and corrosion protection can withstand the stresses or whether improvements need to be made. For this purpose, we have 4 climate cabinets and 3 climate chambers (up to 16 m³).

- For the area of mechanical transport loads, we cooperate with SCUS (Service Centre Environmental Simulation for Packaging Testing) at the same location.

Conformity with EU and national regulations

EXCOR products comply with all currently valid EU regulations.

All VCI packaging products

- may be used without control of indoor air or other restrictions

- can be recycled or used for energy recovery (in accordance with local authority regulations) and are generally considered non-hazardous waste under the EU Waste Directive

- do not contain any CMR substances (carcinogenic, mutagenic, toxic for reproduction)

- are amine-free

- are suitable for components intended to come into contact with foodstuffs

- do not present a hazard through skin contact or inhalation when used as intended

- do not require workplace monitoring according to the Technical Rules for Hazardous Substances (TRGS) 615 and 900.

Our experienced and expert employees continuously monitor current legal developments and implement any necessary measures. Through regular further training, they are always up to date with the latest knowledge.