The future is bright – when you choose EXCOR

Dependable corrosion protection depends on various factors. A good corrosion protection product “alone” is not enough. An effective corrosion protection concept must be tailored to the metal goods requiring protection, the packaging, the packaging process and the transport, i.e. the specific application in each case.

In over 30 years, EXCOR has optimised a large number of applications for its customers and built up a wealth of experience. This has resulted in a large number of product variants.

What exactly does the application of effective corrosion protection involve, and which product is the right one? It’s about:

- Introduction of VCI corrosion protection into the transport packaging

- VCI quantities determination

- Effort optimisation

- Enveloping or additive solution

- Packaging solutions – such as interlayers, cushioning, fixing, stacking, tightness

- Re-use

- Recycling/disposal

To find the optimal solution for our customers, we take these aspects into account and adopt a holistic approach: From process inspections to comprehensive analyses and packaging development, to knowledge transfer for your employees, we help you ensure that your packaged goods reach their destination free of corrosion.

Our approach

To develop a suitable solution for your goods requiring protection, we first have to get to know all the application-related work steps at your site. This also includes checking the process media used in the mechanical processing, the cleaning and preservation of the respective goods.

VCI corrosion protection is the last link within a process chain. The preceding machining, cleaning and storage processes can leave residues on metal surfaces and thus hinder any kind of corrosion protection (or even trigger a corrosive effect themselves), because the corrosion protection agent must be able to reach the metal surface. Purchased metal components, e.g. in the automotive industry, are not subject to in-house production control and are often not free of corrosive residues. During the application, this corrosion risk is noticed only when temperature fluctuations wet the metal surface with condensed water vapour and thus bring about corrosion, i.e. when damage has already occurred. We try to rule that out. To accurately assess residues and ensure the best possible effect of the volatile corrosion protection, we offer a professional analysis service in our laboratory. Which procedures are used here you can find out under “Corrosion research”.

In addition to dependable corrosion protection, there are other requirements for VCI packaging. EXCOR can develop (or even optimise) the entire packaging process for an application (CAD presentation and prototyping). The objectives are:

- Maximum VCI corrosion protection

- Transport security depending on the destinations and stresses involved

- Reduction in labour and material costs

- Single-use or multi-use

- Environmental compatibility

Our highly qualified packaging specialists will develop the right solution for you that can be optimally integrated into your existing processes. We take into account the shipping method used, the duration, climatic conditions, storage and planned retention time in the packaging.

By means of climatic and mechanical tests of a packaging unit, we can simulate the most critical conditions to be expected. Chemical-physical tests can be used to determine the corrosion risks for a metal part. In this way, we detect unexpected weaknesses in the packaging or extreme sensitivity of the packaged goods and can compensate for them in a targeted manner. Prevention avoids unpleasant surprises.

The climatic stress test DIN EN IEC 60068-2-30 is a method developed from many decades of experience to simulate the pitfalls of worldwide climates in their harshest expected effects on a packaging unit in condensed form. A harsh climatic stress does not occur in every shipment, but it could.

EXCOR can perform these tests in three dedicated climatic chambers with up to 16 m3 volume and in four climatic chambers. Test results are professionally documented and damage is shown photographically and microscopically, if necessary. If necessary, recommendations are made for possible improvements.

Mechanical packaging tests are also carried out according to standardized specifications. The tests differ depending on the shipping unit (package or loading unit) as well as the type and duration of transport. The transport route determines the test procedure: a truck transport to far Eastern Europe or a rail transport on the new Silk Road or a parcel shipment require different parameters.

Chemical-physical tests detect traces of corrosive and other contaminants on metal surfaces, as they often occur as machining residues. When exposed to moisture, these can undermine corrosion protection and thus promote corrosion. EXCOR has the equipment and experience to find such impurities, assign them to appropriate processes if necessary, and make recommendations on how to avoid them.

The right active ingredient group for every metal

In addition to commercially available multi-metal protection systems, EXCOR offers VCI active ingredient types that are tailored to specific metal types. This is because there is no VCI product that protects all types of metal in the same way. Depending on the metal type, the dependability of the VCI corrosion protection can be further increased with the specific types of active ingredient.

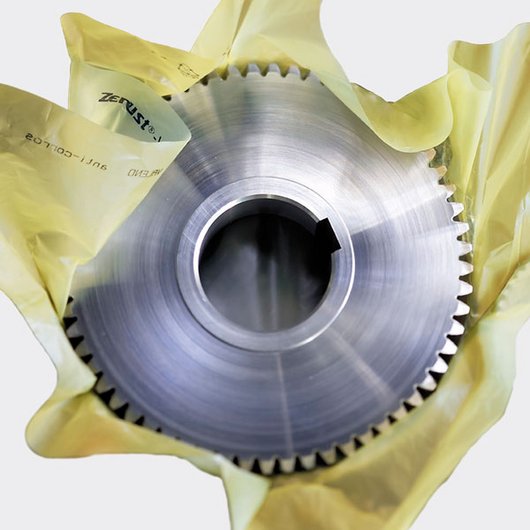

Contact partners around the globe

EXCOR is embedded in the international Joint Venture System of Northern Technologies International Corporation (NTIC). EXCOR and its sister brand Zerust are, therefore, present in a total of 52 countries. The joint venture system enables EXCOR to operate worldwide and at short notice, e.g. to carry out inspections, perform sample shipments or even have damage investigated by experts.